In the heart of Italy’s textile industry, where tradition meets innovation, a small but renowned workshop has achieved what many considered impossible: crafting a 0.1mm ultra-thin cashmere fabric. This remarkable feat is not just a triumph of engineering but a testament to the relentless pursuit of perfection that defines Italian craftsmanship.

The journey to create such an exquisite material began with a simple yet audacious question: How thin can cashmere go without losing its legendary softness and warmth? For years, cashmere has been synonymous with luxury, prized for its lightweight feel and insulating properties. But pushing it to a mere 0.1mm thickness required rethinking every step of the process, from sourcing the finest fibers to weaving them with unprecedented precision.

At the core of this challenge was the selection of raw materials. Only the undercoat of Himalayan goats, harvested during the spring molting season, possesses the fineness required for such a delicate fabric. The artisans worked with herders in Mongolia and Nepal to secure the rarest and softest fibers, each strand measuring no more than 13.5 microns in diameter. Even then, only the most flawless strands were chosen, as any imperfection would be magnified in the final product.

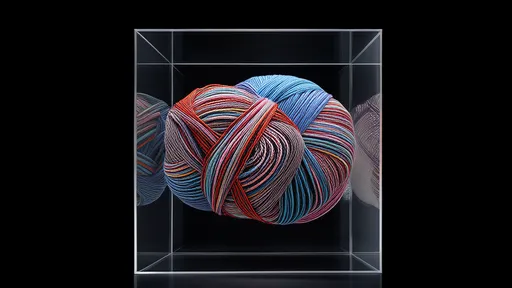

The spinning process demanded equal precision. Traditional methods were too harsh for fibers this delicate, so the workshop developed a proprietary technique that minimized tension and friction. By adjusting the humidity and temperature in the spinning room, they ensured the fibers remained supple and intact. The result was a yarn so fine it seemed almost ethereal, yet strong enough to withstand the next critical phase: weaving.

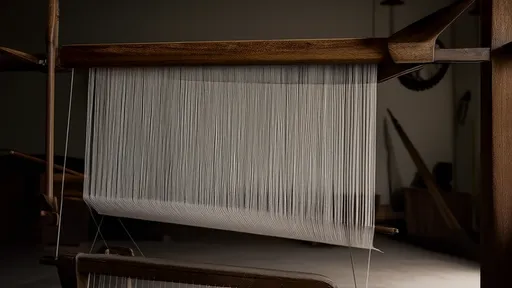

Weaving 0.1mm cashmere required looms that could handle the fragility of the yarn without breaking it. The workshop collaborated with engineers to modify antique Jacquard looms, integrating modern sensors to monitor tension in real time. Each pass of the shuttle had to be flawless; a single misstep could ruin hours of work. The weavers, some with decades of experience, described the process as "dancing with the threads," where patience and intuition played as much a role as technical skill.

Finishing the fabric was another hurdle. Traditional brushing and washing techniques would have destroyed the delicate weave, so the team developed a gentle finishing method using air-infused water and microscopic brushes. The final step involved a painstaking inspection under magnifying lights, where any imperfections were corrected by hand. The result was a fabric so light it could float on a breath, yet warm enough to rival thicker alternatives.

This breakthrough has far-reaching implications. In fashion, designers are already envisioning garments that combine the weightlessness of silk with the warmth of cashmere—think feather-light scarves that fold into a pocket or summer-weight coats that defy seasonal boundaries. Beyond clothing, the fabric could revolutionize luxury interiors, offering ultra-thin yet insulating drapes or blankets for high-end homes.

Yet, the true significance of this achievement lies in its celebration of human ingenuity. In an age of mass production, this Italian workshop has proven that there is still a place for obsessive attention to detail, for the marriage of old-world techniques and cutting-edge technology. The 0.1mm cashmere is more than a fabric; it is a statement that perfection, no matter how elusive, is always worth pursuing.

As the workshop’s master weaver puts it, "We didn’t just make cloth. We touched the impossible." And in doing so, they’ve redefined what luxury can be.

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025

By /Aug 1, 2025